TWISTED-IN-WIRE BRUSHES

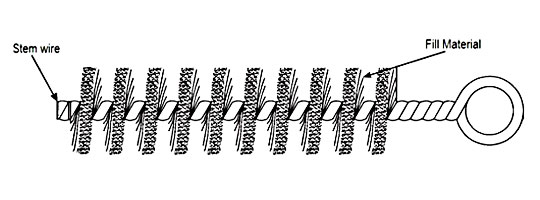

Twisted-in-Wire brushes are made by placing filament material between stem wire and twisting it to produce a spiral shape brush. The construction of the brush paired with a particular filament is the key to the versatility of this brush type. Commonly used for cleaning, polishing, removal of burrs and other surface preparation, they are designed to meet a variety of application and abrasion requirement.

HOW IT’S MADE

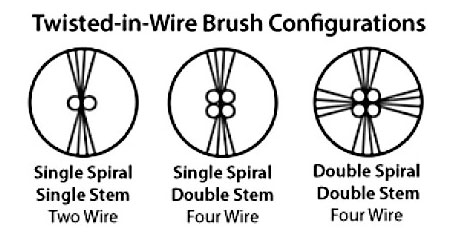

Twisted-in-Wire brushes are categorized into three different configurations and include a broad range of filament, tip and end options.

SINGLE SPIRAL/SINGLE STEM (2 WIRE)

Brush fill is twisted between two stem wires with a single wire on each side.

SINGLE SPIRAL/DOUBLE STEM (4 WIRE)

Brush fill is twisted between four stem wires with two stem wires on each side.

DOUBLE SPIRAL/DOUBLE STEM (4 WIRE)

Brush fill is twisted between four stem wires with two layers of fill. Each layer is perpendicular to the other with a single stem wire in each quadrant.

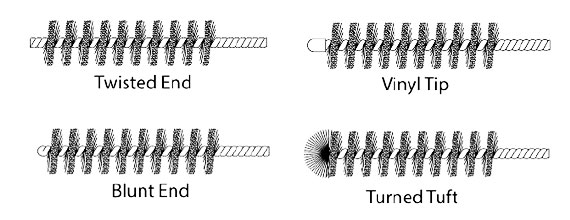

OPTIONS

The tips of the wire filament do the work. Excessive pressure bends the filament, resulting in excessive flexing, premature breakage and reduced brush life. Our engineers take into account the specific diameter, length, weight, tips, end and filament when selecting the precise brush for your application.

BRUSH FILAMENTS

• Nylon

• Polypropylene

• Brass

• Stainless Steel

• Carbonized Steel

• Custom

END HANDLES

• Pipe Nipple

• Wood Handle

• Plastic Handle

• Straight Stem

TIPS

• Twisted End

• Vinyl Tip

• Blunt End

• Turned Tuft

• Tied Tuft