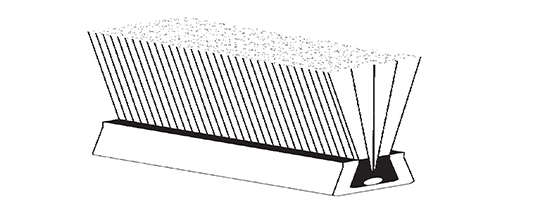

METAL BACK STRIP

Metal Back Strip brushes consist of densely compressed filaments laid down over a continuous metal channel, and then formed into a “U” shape. Common applications are shields, light exposure, air flow, particulate build-up, cleaning, sound/noise or containment.

HOW IT’S MADE

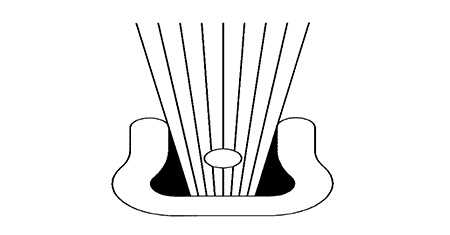

A core wire is inserted over the filament material and formed down into the metal backing. The core wire directs the wires vertically as the metal backing form closes over the core.

METALLIC STRIP/BACKING IS AVAILABLE IN GALVANIZED STEEL OR STAINLESS STEEL.

The backing typically works with the desired bristle diameter and density.

SIZES RANGE FROM #3 TO #10

Channel backing, width, and overall heigh will vary depending on the fill amount.

ONCE FORMED, THE BRUSH CAN BE MOUNTED OR SHAPED IN VARIOUS MANNERS SUCH AS SPIRALS, CUP OR RING.

OPTIONS

Metal back strips can be mounted either as an alligator clip or an extruded aluminum holder. The probes on the alligator clip wrap around the brush to allow a tight hold on a section of the strip brush.

BRUSH FILAMENTS

• Nylon

• Polypropylene

• Brass

• Stainless Steel

• Custom Filament

TRIM PROFILE

• Flat

• Bevel

• Saved End

• Offset

• Stepped

TRIM SHAPE

• Helical

• Internal Ring

• External Ring

• Formed Cup Brush

• Formed Strip Brush

• Straight

• Coiled