CONVEYOR SYSTEM CLEANING

Extend the life of your conveying system, improve quality control, and and reduce operator fatigue. Schaefer Brush’s channel and I-Beam sweeps provide continuous cleaning of all internal surfaces of floor-mounted or ceiling-mounted conveyor systems.

PROVIDES CONTINUOUS CLEANING

Eliminates particle build-up and fall out. Reduces rework of painted parts due to contamination. Reduces wheel and chain wear, and other costly down time expenses. Easy installation and non-sparking brush filament make this the ideal after market addition to your conveyor line.

Custom brushes can be made in any style, including:

CHANNEL SWEEP

Fits Webb-Unibilt 20200, Richard-Wilcox Model 2035, and Adams Chainveyor 200 Series

BEAM SWEEP

I-Beam sweeps designed for 3″ Beam and 4″ Beam with top, bottom, and side brushes

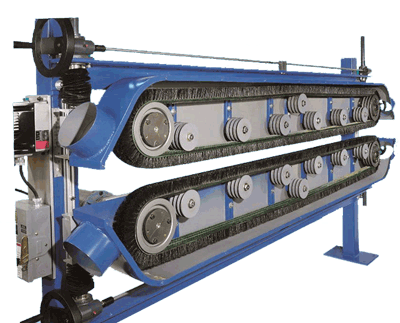

S-VECO CONVEYOR SYSTEM

Cleans top and bottom of conveyor belt, modular design to fit your exact needs

S-VECO BELT BRUSH

S-Veco Belt Brush linear cleaning system are idea for conveyor cleaning and as belt brushes are idea for wood and metal finishing processes. S-Veco is the only linear system designed to be self-cleaning. The brush belt operates in a perpendicular or transverse direction to the item being brushed, utilizing a powered Uni-V Belt tufted with brush fibers that will best suit the application.

The brush belt travels at a 90-degree angle across a series of sheaves. As it passes over the sheave, the opening of the brush fiber allows debris to be removed by force and easily collected. The belt brush cleaning system can be set up over or under a conveyor.